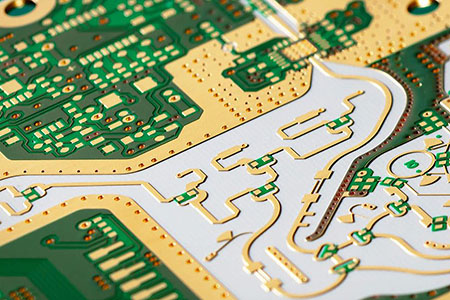

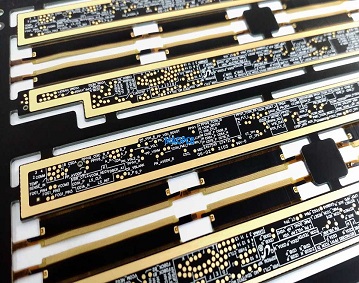

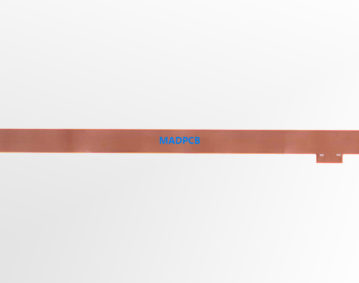

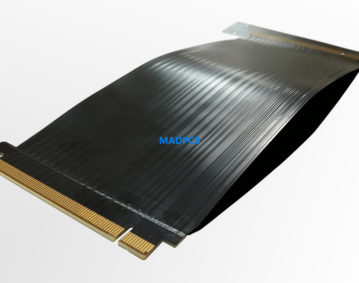

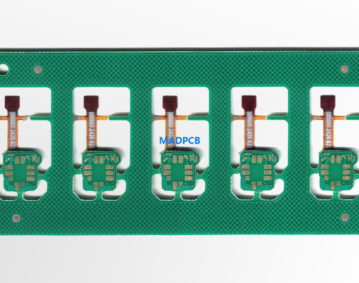

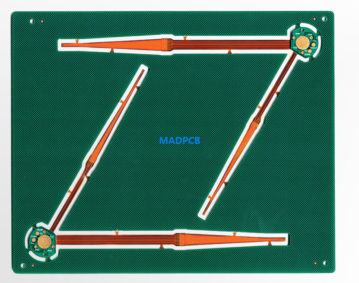

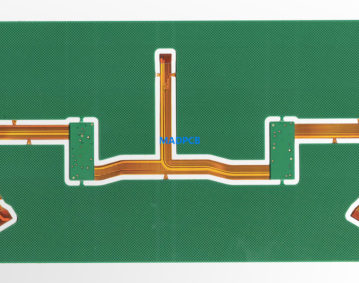

• PCB Capabilities: Rigid, IMS, Flex- & Rigid-Flex

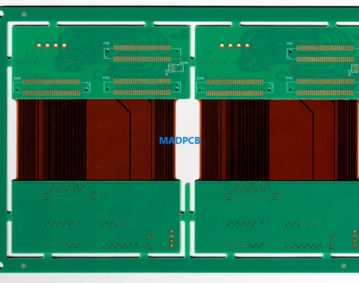

• Layer: Rigid 1-30, Flex PCB 1-8, Rigid-flex 1-20

• Via: Thru-Hole, Blind & Buried Vias & Microvia

• Quality: IPC Class 2 and 3

• CCL Material: FR4, PTFE, PI (Kapton), Metal Core

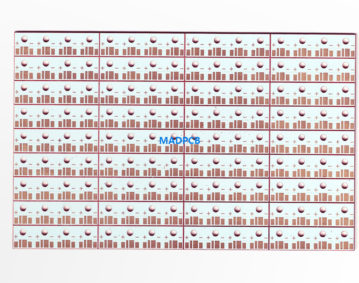

• MOQ: 1pc PCB prototype

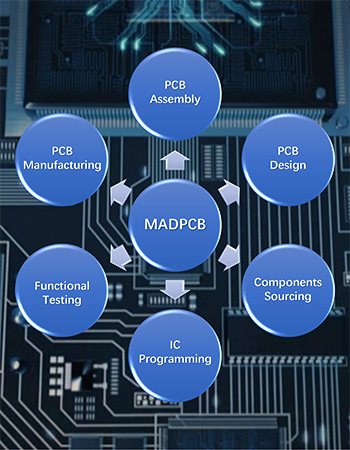

Contract Manufacturing Services

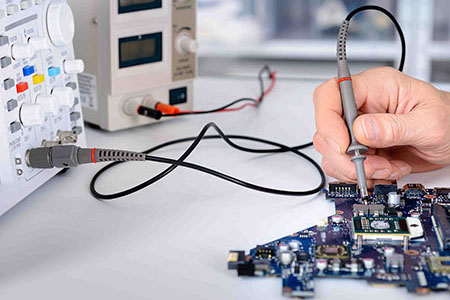

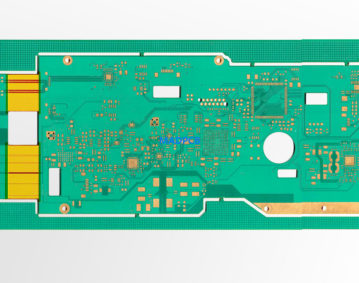

PCB Manufacturing

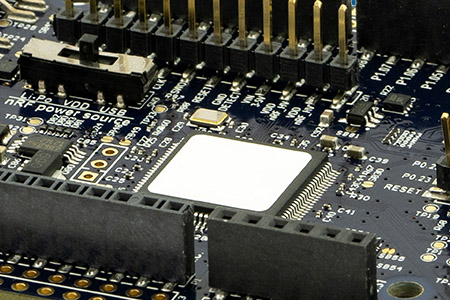

PCB Assembly

• Technology: SMT, DIP, Press-Fit, Hand Soldering

• Type: Single- and Double-Sided Assembly

• Assembly Process: Tin Lead-free, Tin-Lead

• Tooling: Stencil, SMT Carrier, Depaneling Carrier

• Components: Turnkey, Kitted, Combo

• MOQ: 5pcs prototype PCB assembly

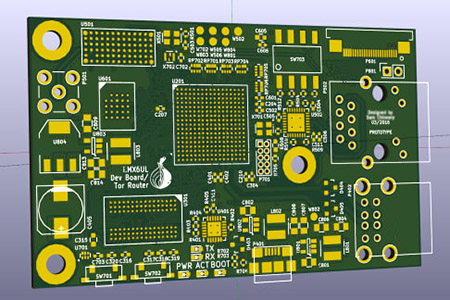

PCB Design

• Digital, Analog, RF, Low Noise, High Voltage

• Controlled Impedance /Length Matching

• 0.35mm μBGA to 2,200+ pin BGAs

• XAUI, PCIe, SerDes, LVDs, Gig-E…

• DDR2, DDR3, DDR4, DDR5 memory

• Reverse Engineering

Components Sourcing

• Quick BOM Quote

• Global Components Procurement

• Custom Enclosure & Packages

• Components Management & Stock

• Full Traceability

• Supply Chain Management

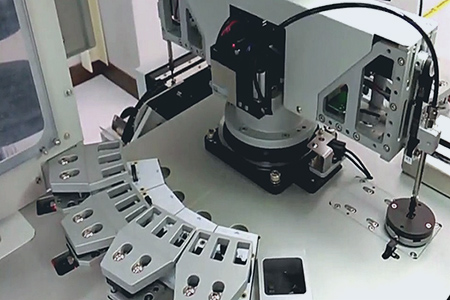

IC Programming

• MPU/MCU, EPROM, EEPROM, Flash Memory…

• DIP, SOP, PLCC, QFP, QFN, MLF, BGA, CSP, SOT…

• Binary, Intel Hex, SREC, TEK HEX, XTEK, POF

• Custom Test Jig with Pogo Pins

• Taping & Reeling

• Baking & Dry Packing

Functional Testing

• Opens & Shorts

• Display Testing

• Digital Sections

• Analog Sections

• Communication Testing

• Boundary Scan & JTAG Testing

Why Choose MADPCB?

Full PCB Services

Professional engineers and team directly from PCB manufacturer, PCB assembler and PCB design company, can meet any of your PCB needs under one-roof from MADPCB.

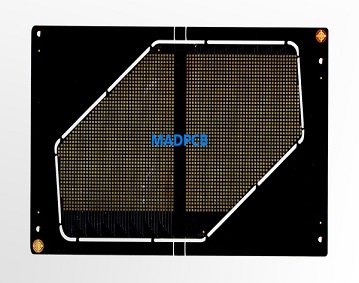

No PCB Quantity Limited

Rigid and flex printed circuit boards (PCB) have no quantity limited, and are acceptable for prototyping and production orders, short- and long-term manufacturing.

Adequate PCB Materials

Always store adequate PCB materials including FR-4 CCL, PTFE CCL, metal core CCL, PI FCCL; RCC, PP, coverlay, adhesive, EMI shielding film and other PCB accessories.

Pre-CAM Support

20+ years experience Pre-CAM engineers can solve rigid board, FPC, Rigid-flex board & HDI PCB problems in stack-up, panelization, Gerber file, controlled impedance and etc.

Original Parts Sourcing

With turnkey PCB assembly service, parts for proto and low-volume PCB assembly are from famous distributors, parts for high-volume PCB assembly are from part manufacturers.

Quick Response & Quote

No matter how complex, we can provide PCB quote in 0.5-2 hours, BOM quote and assembly quote in 24 hours, design quote in 48 hours even if in our weekends.

About MADPCB

Electronics Contract Manufacturer with Full PCB Services

MADPCB is recognized as a reliable Electronics Contract Manufacturer (ECM) with facilities in China, and customers in a variety of technologically advanced markets trust our full printed circuit board (PCB) services covering bare PCB fabrication, assembly, parts sourcing, programming to functional testing. All jobs will be done under one roof to remove your risk, save your energy, time and cost.

Testimonials

Tobias

Germany

My design is a front-end DVR. Two failure experiences with previous PCB assembly house make me understand it’s not easy to find a reliable turnkey PCB assembly manufacturer, especially which can fabricate HDI PCB and solder QFN parts well. From an electrical engineer who works at Jabil, I know MADPCB is the electronics contract manufacturer I can trust. MADPCB builds our prototype PCB assembly, and all PCBAs are proven to work as desired, and we pass some certificates. This is a happy experience, thanks for all guys in MADPCB.

Jacob

USA

The best thing about MADPCB that impressed me the most is the work efficiency, with which everything was done under one roof, including quote, EQ, PCB fabrication, components sourcing and SMT assembly. Their PCB capabilities for small features are much better, and the prices of PCB board and circuit board assembly for the same specifications are reasonable as well. We always treat MADPCB as our priority vendor of PCB manufacturing and assembly, functional testing, and we’ve been working together for many years in some prototyping and high-volume PCB assembly projects.

Chloe

Australia

I received the flex circuits last Friday and they look and operate perfectly under the given frequencies! I want to thank you all MADPCB staff for their skills, patience, fast turnaround, and attention to details in PCB layout and flex PCB fabrication with hatch impedance. I think I shall leave this design as it is, but I’m thinking of combining the FPC with the Ethernet board on the right so we can have a rigid-flex PCB solution. The final design will be presented on my PhD thesis 2019, I will keep you posted when the schematic is ready.

Leonardo

Italy

We got our PCBAs a couple of weeks ago. The assembled boards not only look great but also functional after testing by our engineers. We are very happy with your professionalism, and amazed by your communication and production speed. Besides that, as an electrical engineer, I find no any PCB assembler like you, can joint develop testing jig, programming and conducting electrical testing after PCB board assembly. Thank you for your support along the way for me and our company, and that makes it possible for us to get quick PCB assembly prototyping.